Conclusion Of Stone Crusher

Stone Crushers: A Technical Review on Significant Part of

Stone Crusher is a sort of pulverizer which is utilized to compress or break out assortmentofenormousstones.Itnormallyhighlightsahugecrushingrateandhigh return and

learn more

(PDF) Stone Crushers and Dust Problem - ResearchGate

2012年1月1日 2.3+ billion citations Content uploaded by Dr. Ravindran S. Author content Content may be subject to copyright. ResearchGate has

learn more

(PDF) Design and Performance Evaluation of a Stone

2021年10月7日 In conclusion, the use of the modified hammer mill drastically reduced the non-uniformed particle size associated with most hammer mills as well as eliminates the use of burr mill by farmers in ...

learn more

Stone Crushers: A Technical Review on Significant Part

2022年5月1日 Request PDF Stone Crushers: A Technical Review on Significant Part of Construction Industry Adoption and implementation of innovative solutions is the need

learn more

(PDF) Design of Impact stone crusher machine

2019年5月31日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of ...

learn more

Impacts of stone mining and crushing on environmental health in

Stone dust produced from the crusher units (∼10–11 tons/day) is not only injurious for human health but also other valuable components of the environment like air, water, soil

learn more

Strength and Durability Aspects of Crushed Stone Sand: A

2020年6月1日 In this paper a effort is made to summaries the findings done by various researches and conclusive statement is made about till date study carried in regards of

learn more

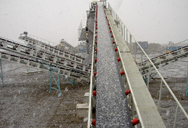

7 Types of Stone Crusher and How to Choose the Best?

2021年9月23日 Summary: Stone crusher is an indispensable part of crushing, sand making, grinding and other processes. This article will tell you how to select the right

learn more

Project report for Stone Crusher Unit

Over 12,000 stone crusher units are expected to exist in India. The number is projected to rise further in light of potential proposals for the construction of infrastructure such as

learn more

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 1 Introduction Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [ 1 ]. In infrastructure industry, these equipment are available in different capacities ranging from 0.1 ton/hr. to 50 ton/hr.

learn more

Aggregate Production Optimization in a Stone-Crushing Plant

2020年2月8日 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction). The CSS,

learn more

Advantages and Disadvantages of 4 Types of Stone

2023年2月15日 Blog details Advantages and Disadvantages of 4 Types of Stone Crusher Machines Author : Jordan Last Updated : Feb 15, 2023 As the key material for infrastructure, natural stones are generally large

learn more

Impacts of stone mining and crushing on environmental health in

Stone dust produced from the crusher units (∼10–11 tons/day) is not only injurious for human health but also other valuable components of the environment like air, water, soil and forest qualities. In consequences of this, temperature is raised by 1–1.5 °C, ...

learn more

Strength and Durability Aspects of Crushed Stone Sand: A Review

2020年6月1日 Crusher dust is a fine material formed during the process of comminution of rock into crushed stone or crushed sand. This dust is composed by particles which pass 75 μm BS sieve.

learn more

Jaw Crusher - an overview ScienceDirect Topics

1. crusher design characteristics such as width and depth of the crushing chamber, 2. open and closed side settings, 3. options on feeding method, e.g., intermittent feeding (manual or direct by haulage trucks) and continuous by conveyor belt, 4.

learn more

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing

learn more

The Ultimate Guide to Crushed Stone and Gravel

2023年4月21日 Crushed stone is a type of construction aggregate that is typically produced by mining a suitable rock deposit and breaking the removed rock down to the desired size using crushers. It is a popular material for use in construction projects, including roads, bridges, buildings, and landscaping.

learn more

Project report for Stone Crusher Unit

Product / Services process If the crushed stone unit is located near the queries, where granite boulders of different sizes are accessible for the crushing unit, it is beneficial. The crushed stone unit would benefit greatly from the granite industry's waste. Jaw crushers are used to reduce the size of granite stones of different types.

learn more

The Engineering Study on the Use of Crushed Stone

Hence, the gradation mixes of crusher dust and Crusher stone aggregate with an addition of 20- 30% with respect to Crusher stone Aggregate attaining CBR value greater than 50 can be recommended as Base

learn more

7 Useful Tips For Stone Crusher Machines Pulverizers

2022年1月25日 Stone crusher machines and pulverizers are mainly used in the following areas: mining, metallurgical industry, building materials industry. Now there are many types and models of stone crusher machines and pulverizers. Here we introduce some tips for choosing a suitable stone crusher machine. The first step you should do before using

learn more

Small Scale Mechanized Stone Crusher, Mechanical Design

conclusion will be drawn based on the analysis found and recommendations given that will seek to further improve the designs of small scale stone crushing machines. This will further evaluate the differences in having a small scale mechanized jaw crusher gap against hammer and anvil crushing mechanisms, from a point of view of economic viability.

learn more

Reason Why You Need a Stone Crusher Machine - Ventil

2019年3月28日 Conclusion. Purchase a stone crusher machine is the best option.Although hiring these machines might seem advantageous at first, but if you calculate the amount to spend on one time purchasing; hiring will be on the higher side. Just make a good market study and identify the best manufacturer you can buy your machine from.

learn more

Maximizing Efficiency and Minimizing Stone Crusher Plant

2023年2月23日 In conclusion, minimizing downtime is a crucial factor in reducing the cost of a stone crushing plant. By implementing a regular maintenance schedule, keeping spare parts on hand, and having a plan in place for dealing with unexpected downtime, you can help to ensure that the plant is operating at maximum efficiency and that any downtime is

learn more

How to Control the Discharge Size in Crushing Stone and Sand?

2023年2月15日 Crusher is the common equipment of sand and stone industry that is often used to break large stones, and it has a lot of different types and specifications with different discharge sizes. Understanding the specifications of finished materials can provide necessary reference for users to select equipment .

learn more

Design and Fabrication of Multi-purpose Sieving Machine

International Journal of Research in Engineering and Science (IJRES) ISSN (Online): 2320-9364, ISSN (Print): 2320-9356 ijres Volume 9 Issue 7 ǁ 2021 ǁ PP. 44-49 ijres 44 Page

learn more

Jaw Crusher - an overview ScienceDirect Topics

Rose and English [9] determined the capacity of a jaw crusher by considering the time taken and the distance travelled by the particles between the two plates after being subjected to repeat crushing forces between the jaws. Therefore, dry particles wedged between level A and level B (Figure 4.4) would leave the crusher at the next reverse

learn more

The Ultimate Buying Guide to Crushed Stone and Gravel

In general, as the number goes up, the size of the gravel goes down. Here’s an overview: #1 - The largest size. Particles are usually between 2-4 inches in diameter. #3 - Somewhat smaller than #1. Particles are usually ½ - 2 inches in diameter. #5 - Particles are 1 inch or smaller in diameter.

learn more

Project report for Stone Crusher Unit

Over 12,000 stone crusher units are expected to exist in India. The number is projected to rise further in light of potential proposals for the construction of infrastructure such as bridges, canals, and buildings that are essential for the country's overall development. ... Conclusion The project as a ...

learn more

Study on Compressive Strength of Quarry Dust as Fine

2016年4月10日 With observation of 20% of quarry dust (7 days), the average compressive strength is 29.62 N/mm 2 whereas that for natural sand is 28.44 N/mm 2. For 25% quarry dust, the value increased to 30.81 N/mm 2. Finally, for 30% quarry dust, the strength increased to 32.88 N/mm 2.

learn more